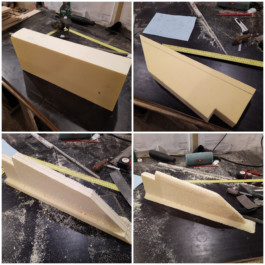

SKEG

11/04/2020

Since January it was pretty impossible to me to work on the boat. The weather condition here in Zurich didn't allow any work on the main structure, like gluing big parts.

Because temperature were easily below zero degrees, even with all the time and money i did invest in doubling the tent and isolating the roof, installing various heating system, the conditions were not good enough to glue the planking. I just did not wanted to have a boat who might start disassemble or broke apart in the middle of the ocean because i was not able to wait the right conditions to let the epoxy glue cure properly. So this last few months were actually quite a big test of patience and being resilient with events I don't have the single leverage on. Like the weather. Pretty important as a sailor i guess.

So no big work, but hips of small items and object I could easily build in a heated room and let to cure, dry safely in a sort of dryer, or owen. I was then able to build the skeg of the boat, this part is the one who is going to hold the lower rudder hinges. This is a piece 100% made of glass fiber and epoxy. Plus a row of 6 bolts, welded together on a metal stringer and place in the empty mold before that one is filled with epoxy and more glass fiber pieces.