PLANKING and shaping the hull

15/07/21

This important step went pretty easily. It just need some patience and precision.

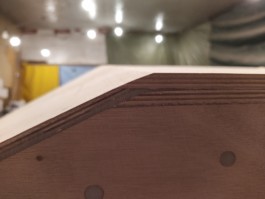

First of all I dry fit all the plywood plate on the structure. With the pencil marks from the CNC kit it is very easy to double check if there is any wrong measurement at that point. I pre-drill the hole and countersunk them so that no head screw got the chance to disturb the flatness of the hull. Each screw was after covered with some epoxy glue fairing peanut butter.

It went pretty straight forward. One day top side and the first layer of the bottom layer. and the next day shaping a little the edge to make a perfect match between the middle layer of ply. Went the glue is cured i found it very satisfaction to use a wood planner to remove all the extra with on each piece of plywood. Wood chips and sawdust everywhere around me and on me as well.

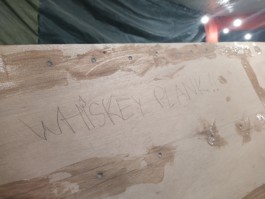

The whiskey plank is normally the last plank on traditional wooden planked boat. And celebrated with a bottle of whiskey. Even if this little 580 is not build with traditional plank we celebrate the last plywood panel like it should be. ChiNCHIN. Prost, VIVA

To glue the second bottom layer I used a polyurethane wood glue, Collano SAMPAROC. Even if i did use some glue that stuff is so nasty ans sticky. a real pain to remove when on your hand or any tools. I did apply a the bow pane first and move slowly toward the transom. To be sure my plywood would be exactly flat on the first panel i used tiny stainless screw (3.5X16mm) to connect the two layer together. And did drill many holes on the outside ply so that the extra glue can overflow though them.

The day after an other wood planer action to trim the shape of the hull perfectly, breaking all the edges because because when applying the fiberglass it has to be rounded because on sharp edges the fiber wont be able to glue properly.

Final sanding of the hull and now we really got a boat looking like a boat.

An other whiskey for the boat and for me.

cheers